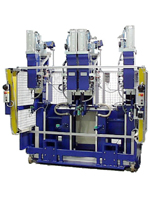

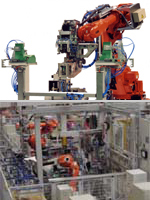

Riveting systems + special-purpose machines

We offer our customers solutions that, where possible, build on standard components.

In this, we take account of the specific requirements of our customers. Jointly with them, we device economical and practical solutions that enable long-lasting and dependable advances to be made in terms of quality. This also includes

- workplace design,

- the automation of machine peripherals or

- integration in complex production systems.

We are an ideas factory and we wish to help our customers improve their performance and their productivity. The right balance should be struck here between the level of automation and flexibility.